-

- Contact details

- Call us: +86-020-36078533 E-mail: [email protected]

- WhatsApp / Phone: +86 13078842050 +86 18027318690

- How To Use Leg Extension And Prone Leg Curl One Machine

- How to use Commercial Treadmill?

- How To Use The Best Seated Leg Extension Hammer Strength Machine

- Customers Testing Fitness Equipment In BFT Fitness Show Room

- BFT Fitness Equipment Factory 2017 Year-end party. 2

- How to Do Lying / Prone Leg Curl Machine

- How to use High Pully|Lat pulldown machine?

- Why spinning fitness is popular all over the world

- How to use Functional Trainer & Smith Machine?

- What’s the difference between losing weight and losing fat?

Current Location: Home > News > >

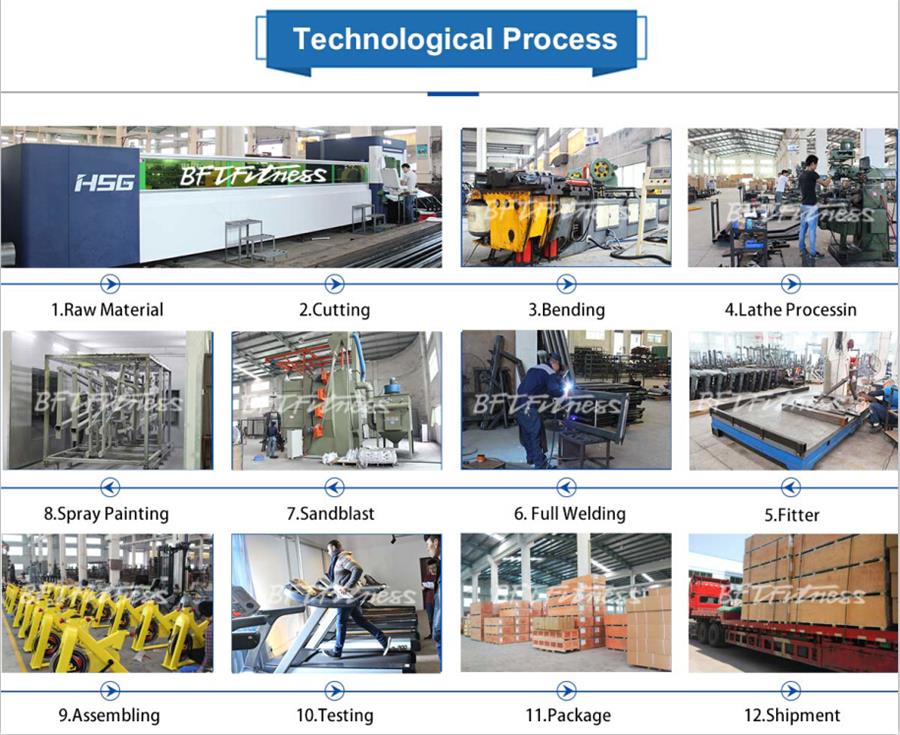

Fitness equipment production process

Fitness equipment production process

The numerical control laser cutting machine is characterized by its fast cutting speed and small cutting seam in the cutting process. Not only can it cut and punch holes in all kinds of metals and materials with high-speed and precision, but also guarantee high cutting quality throughout the cutting process with the help of CNC machine.

And next the tubes will go through bending and welding stage where they will be welded and assembled into semi-finished products. During this stage, the semi-finished products will be put into the first round of Quality Control Test to avoid or remove some potential product defects.

When the first round of Quality Control Test is finished, the semi-finished products will be moved into Sandblasting facility to remove rust layer before being sprayed and painted different colors according to customers' requirements.

After the spray coating is completed, these semi-finished products will undergo the final Quality Control Test to eliminate potential product defects. With guaranteed product quality, all items are tested by using precision electronic instruments before packing and delivery to clients.

If you want to buy gym equipment,you can contact us ! We are manufacturers !

Contact us now for a no obligation free quote.

Related Article

+86 18027318690

+86 18027318690 +86 13078842050

+86 13078842050

+86 020-36078553

+86 020-36078553